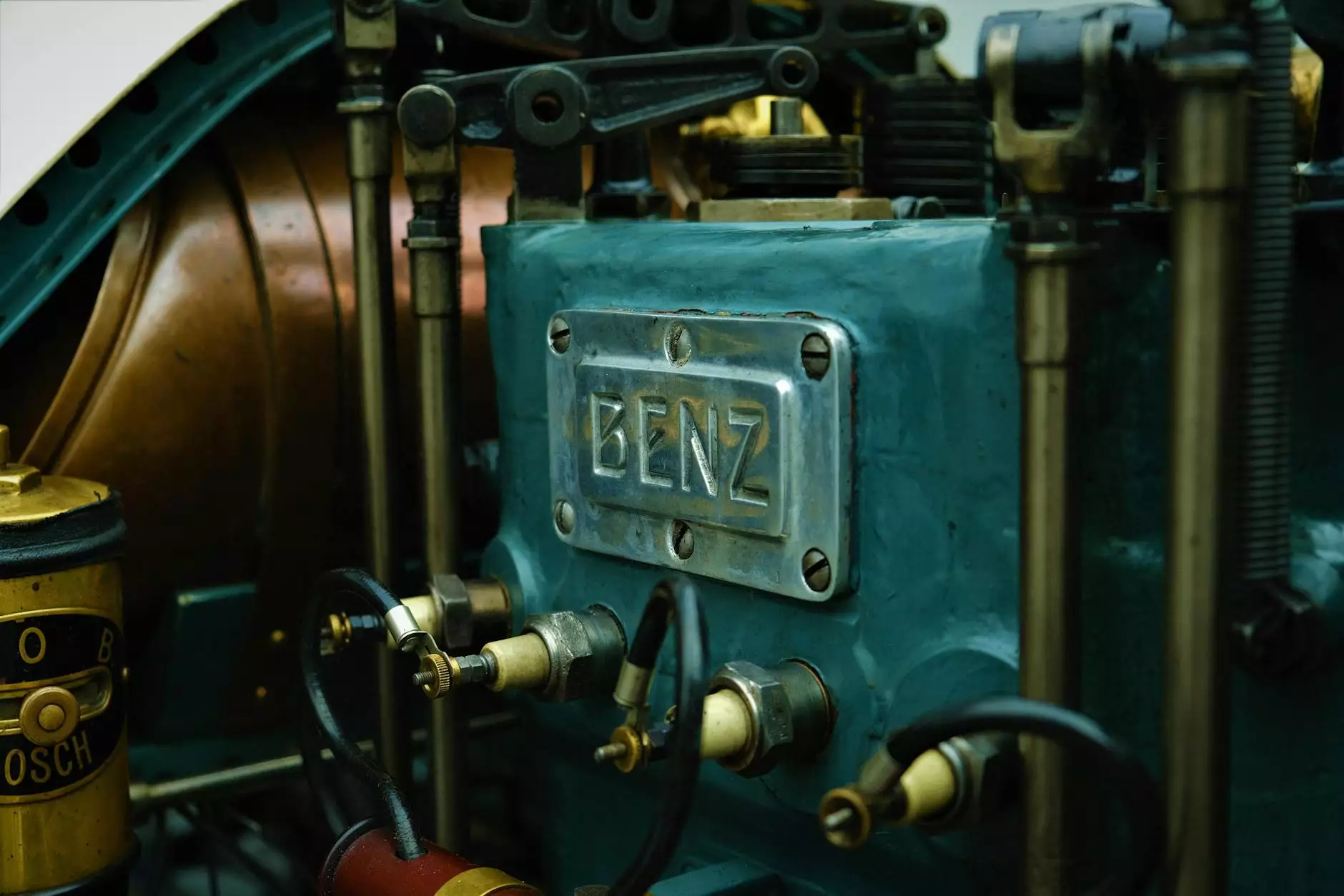

Understanding Solenoid Valve Parts in Diesel Engine Applications

The solenoid valve part is a critical component within diesel engines and various industrial applications. These parts serve as the operational heart of many systems, controlling the flow of fluids with precision and reliability. In this article, we will delve deep into the functional dynamics of solenoid valves, the different components involved, and their importance in ensuring optimal engine performance.

What is a Solenoid Valve?

A solenoid valve is an electromechanical device used for controlling the flow of liquids and gases. It utilizes an electric current to create a magnetic field, which in turn opens or closes the valve. This mechanism allows for accurate and quick adjustments in various applications, making it essential in managing complex fluid systems.

The Role of Solenoid Valves in Diesel Engines

In the world of diesel engines, solenoid valves play an integral role in regulating fuel supply, managing exhaust systems, and controlling other critical functions. Understanding how these valves operate can help in maintaining the efficiency and longevity of diesel engines.

Components of a Solenoid Valve Part

To fully appreciate the importance of a solenoid valve part, let’s break down its key components:

- Coil: The coil generates a magnetic field when electricity passes through it. This field is responsible for actuating the valve.

- Plunger: The plunger is a movable core that responds to the magnetic field. When the coil is energized, the plunger moves to either open or close the valve.

- Spring: The spring provides resistance against the plunger's movement, ensuring that the valve returns to its default position when de-energized.

- Body: The body houses all the components and connects to the fluid lines. It's typically made of durable materials to withstand high pressure and temperatures.

- Ports: These are the entry and exit points for fluids. Depending on the design, valves can have multiple ports.

Types of Solenoid Valves

Solenoid valves come in various configurations to meet specific application needs, particularly in diesel engines. Here are the primary types:

- 2-Way Solenoid Valves: These valves have two ports and are used for simple on-off control.

- 3-Way Solenoid Valves: These are used to control the flow between two different paths, useful in applications requiring complex flow management.

- Normally Closed (NC) and Normally Open (NO) Valves: NC valves remain closed when not energized, while NO valves remain open. Choosing the correct type depends on the specific needs of the system.

- Bistable or Latch Solenoid Valves: These valves can hold their position even after the power is turned off, making them ideal for applications that require minimal energy consumption.

The Importance of Quality Solenoid Valve Parts

Investing in high-quality solenoid valve parts is essential for the following reasons:

- Performance: High-quality parts ensure that valves operate smoothly and respond quickly to control signals, which is crucial in dynamic conditions like those found in diesel engines.

- Durability: Premium components resist wear and tear, leading to reduced downtime and maintenance costs.

- Safety: Reliable solenoid valves prevent leaks and hazardous failures, ensuring safe operation within your machinery.

How to Choose the Right Solenoid Valve Part

Selecting the appropriate solenoid valve part requires consideration of several factors:

- Compatibility: Ensure the valve is compatible with your engine's specifications and fluid types.

- Voltage Requirements: Check the voltage rating needed for activation; different applications may require different voltages.

- Size and Flow Rate: Choose valves based on the necessary size and flow requirements of your system.

- Material: Opt for materials that can withstand the specific environmental conditions of your application.

- Manufacturer Reputation: Select parts from reputable suppliers like client-diesel.com to ensure quality assurance and reliable support.

Maintenance Tips for Solenoid Valve Parts

Proper maintenance of your solenoid valve parts can greatly extend their lifespan and reliability. Here are some practical tips:

- Regular Inspections: Conduct periodic assessments of the valves for any signs of wear or damage.

- Cleaning: Keep valves clean from debris and buildup that may interfere with their operation.

- Electrical Checks: Ensure that electrical connections are secure and that the coils are functioning properly.

- Fluid Testing: Regularly test the fluids being controlled to ensure that no contamination is affecting the valve performance.

- Replace Worn Parts: Keep an inventory of critical spare parts and replace components as needed to prevent failures.

The Future of Solenoid Valves in Diesel Engine Systems

As technology evolves, so too do solenoid valves and their applications within diesel engine systems. Innovations such as:

- Smart Valves: Incorporating IoT capabilities for real-time monitoring and control.

- Advanced Materials: Enhanced materials that withstand more extreme conditions.

- Energy-Efficient Designs: Optimization for lower power consumption without sacrificing performance.

These advancements promise to revolutionize how solenoid valves operate, offering greater efficiency and effectiveness in managing diesel engine functions.

Conclusion

In summary, the solenoid valve part is a pivotal element in the functionality of diesel engines. Understanding its components, types, and maintenance can significantly impact the performance and longevity of your equipment. By selecting high-quality parts from trusted suppliers such as client-diesel.com, businesses can ensure optimal operation and prolong the lifespan of their diesel engines. As we look to the future, embracing innovations in solenoid valve technology will be essential for staying competitive in an ever-evolving industry.

For more information on high-quality diesel engine parts and reliable spare parts suppliers, do not hesitate to reach out or explore our offerings at client-diesel.com.